Learn How Granite Monuments Are Designed and Built

| A rubberized stencil is created for each memorial. It is then affixed to the granite with a special adhesive. Specific areas of the stencil are then removed to create a space for inscriptions and artwork. The marker will then be ready for the first step in the sandblast process. (See Below) |

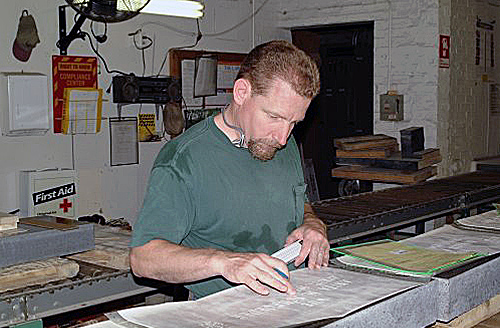

A careful inspection of the stencil for accuracy of spelling and layout precedes the placement of the stencil on the stone. (See Below)

After the stencil is applied to the surface of the granite, the design process begins by exposing certain areas of polished stone to sandblast in preparation for ornamentation and lettering. (See Below)

A rubber mallet is used to tightly secure the stencil to the stone before it enters the sandblast. (See Below)

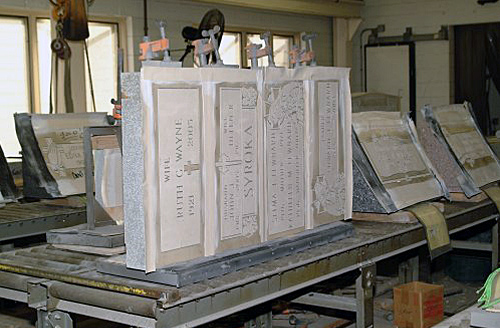

This is a staging area for markers and monuments after the initial sandblast. After they have been inspected for accuracy, these Lawn level markers are moved on the conveyor belt to the final sandblast area. (See Below)

Adhesive and rubber are applied to the stone to protect any exposed surfaces during the blast process. (See Below)

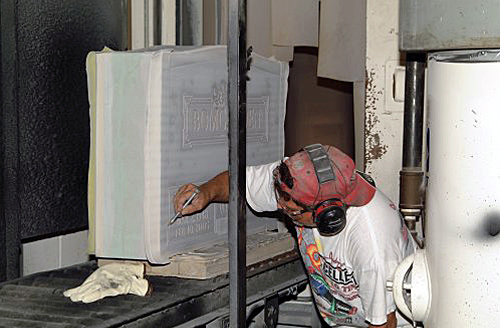

A craftsman with 30 years of experience, hand-sculpts roses on a monument. (See Below)

As the shape-carved roses are cut by hand, they are inspected by our expert craftsmen. (See Below)

A visual inspection of the stencil prior to sandblast is done to insure quality at every step. (See Bellow)

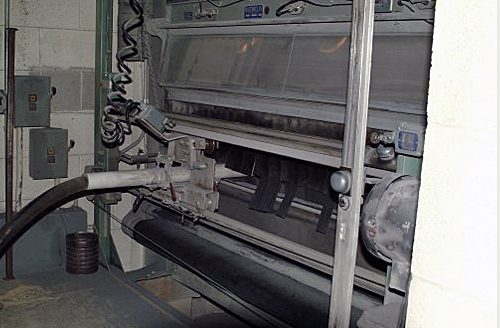

An automatic sandblast machine produces a uniform depth of blast to create the memorial. (See Below)

During the blast process, a visual inspection monitors depth and consistency of lettering and design. (See Below)

After the final sandblast process is complete, markers are prepared for the application of a darkening agent which highlights letters and designs. (See Below)

During the final process of manufacturing, the stencil that was used to create the design and the lettering must be removed. This Troost employee will clean the stone to remove the adhesive that kept the stencil in place during the sandblast. (See Below)

Certain styles of lettering and design require hand-chiseling and texturing to enhance the finished memorial. This process replicates procedures that have been utilized in the granite industry for years. (See Below)

These finished markers are on our loading dock awaiting delivery to the various local cemeteries. (See Below)